Exploring Advancements in Electric Vehicle Battery Technology

Electric vehicles (EVs) are transforming the automotive landscape, driven significantly by continuous innovation in battery technology. These advancements are crucial for extending driving range, reducing charging times, and enhancing overall vehicle performance. The ongoing research and development in battery materials, design, and manufacturing processes are paving the way for more efficient, sustainable, and accessible electric mobility solutions for consumers and industries worldwide.

The evolution of electric vehicle battery technology is a cornerstone of the broader shift towards sustainable transportation. As global demand for EVs grows, the focus on improving battery performance, longevity, and cost-effectiveness intensifies. Innovations in this field are not only enhancing the practicality of electric vehicles but also influencing their design, safety features, and integration into smart mobility ecosystems.

Advancements in Electric Battery Materials

Progress in battery technology is heavily reliant on the development of new materials. Lithium-ion batteries currently dominate the EV market, but researchers are actively exploring alternative chemistries and enhanced material compositions to overcome existing limitations. Efforts include increasing energy density, which allows for longer driving ranges, and improving power density, which contributes to faster acceleration and charging. Solid-state batteries, for instance, represent a significant area of future innovation, promising higher energy density, improved safety, and potentially longer lifespans compared to current liquid electrolyte designs. The exploration of different cathode and anode materials, such as nickel-rich cathodes or silicon-based anodes, aims to optimize performance characteristics and reduce reliance on critical raw materials.

Battery Design and Enhanced Safety

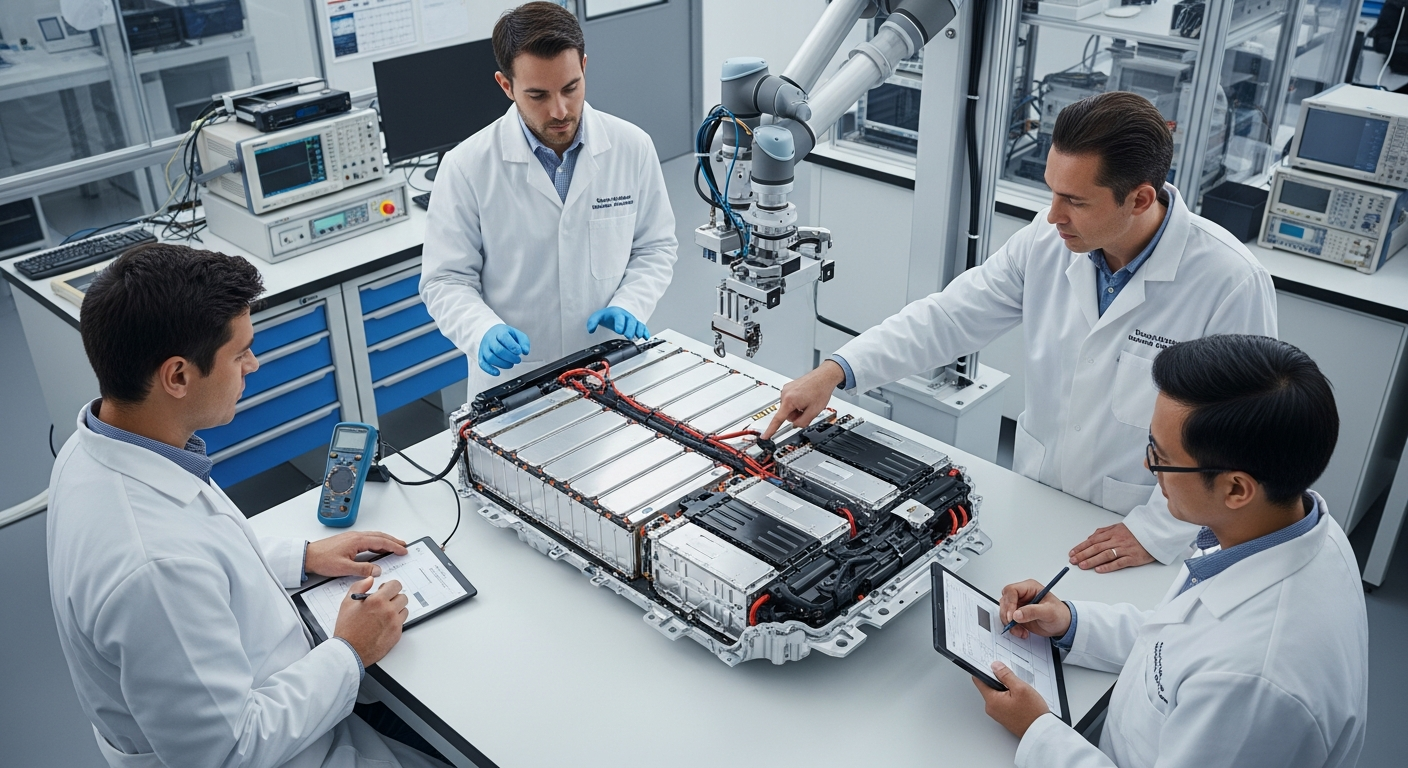

Beyond material science, the physical design of battery packs plays a critical role in an electric vehicle’s performance and safety. Modern battery packs are engineered to be an integral structural component of the vehicle chassis, contributing to overall rigidity and crashworthiness. Advanced thermal management systems are essential for maintaining optimal operating temperatures, preventing overheating, and extending battery life. These systems utilize sophisticated cooling mechanisms, including liquid cooling or phase-change materials, to regulate temperature effectively across individual battery cells. Furthermore, robust Battery Management Systems (BMS) are crucial for monitoring cell voltage, current, and temperature, ensuring safe operation and preventing overcharging or deep discharging. Cybersecurity measures are also increasingly integrated into BMS to protect against unauthorized access and ensure system integrity, especially as vehicles become more connected.

Powertrain Integration and Manufacturing Innovations

The integration of the battery with the electric powertrain is fundamental to maximizing a vehicle’s efficiency and dynamic capabilities. Optimizing the electrical architecture and power electronics ensures efficient energy transfer from the battery to the electric motors. This seamless integration influences acceleration, regenerative braking efficiency, and overall energy consumption. Significant strides are also being made in the manufacturing processes of EV batteries. Automation, advanced robotics, and AI-driven quality control are enhancing production efficiency, reducing costs, and improving consistency. Innovations in modular battery designs and scalable manufacturing techniques are helping to meet the rapidly increasing demand for electric vehicles globally, contributing to more sustainable and cost-effective production at scale.

Future Innovation and Production Trends

The future of electric vehicle battery technology is characterized by continuous research into next-generation solutions and sustainable production methods. Beyond solid-state batteries, other emerging technologies like lithium-sulfur and sodium-ion batteries are being investigated for their potential to offer higher energy densities or utilize more abundant materials. The focus on circular economy principles, including battery recycling and second-life applications, is also gaining prominence, aiming to reduce environmental impact and improve resource utilization. As vehicles become more autonomous and connected, battery technology will need to support increasing power demands for advanced sensors, computing, and infotainment systems. The convergence of AI with battery management holds promise for predictive maintenance and optimized charging strategies, further enhancing the user experience and extending battery longevity within the broader mobility ecosystem.